Presentation

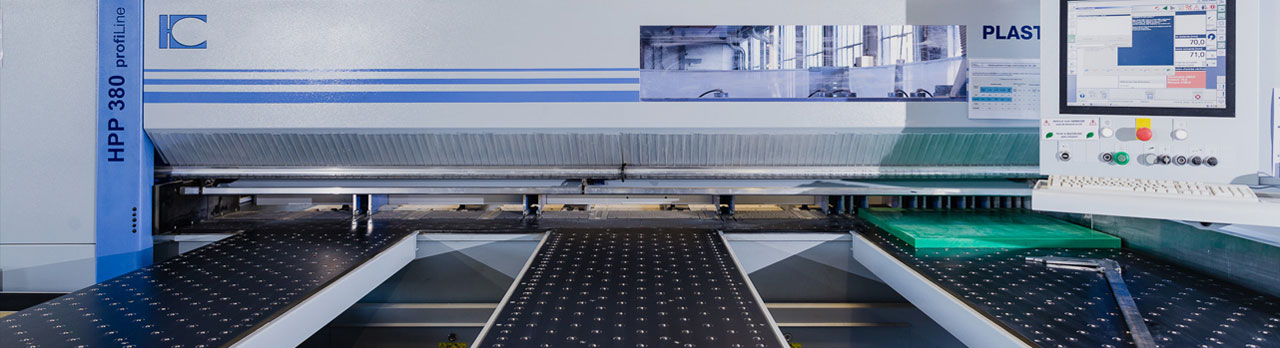

Fringant is an expert in machining sophisticated parts in composites, plastics and cellulosic materials.

Fringant is an expert in machining sophisticated parts in composites, plastics and cellulosic materials.

Since its creation in 1957, FRINGANT INDUSTRIE has adapted to the constant evolution of the industry by continuously monitoring technological developments. A dynamic, qualified team assures not only its subcontracting service, but can assure assembly or specialized sub-assembly.

Thanks to its know-how, its stock of raw material and its digital equipment, FRINGANT INDUSTRIE guarantees optimal service with responses that are adapted to the requirements for machining or sub-contracted machining of each of its clients.

For over 25 years now, this specialization has enabled FRINGANT INDUSTRIE to gain worldwide recognition and to be one of the partners of the biggest industries.

Parts for electric transformers

motors, generators

wind and water turbines

Wood or rigid foam shock absorbers

for packaging nuclear products

for transportation

Sub-contracting of small electricity insulating

composite parts

(washers, plates…)

Diverse heat and electricity

insulating joints

ABB

ALSTOM

JST (Jeumont Schneider

Transformateurs)

ROBATEL

AREVA

GE (Générale Électrique)

SCHNEIDER ELECTRIC

France TRANSFO

TN INTERNATIONAL

…

Disposing of a large and regularly updated stock of raw materials, we work from a very short-term strategy. We are able to keep the time between your order and shipping your parts to a few days.