Nuclear packaging wood

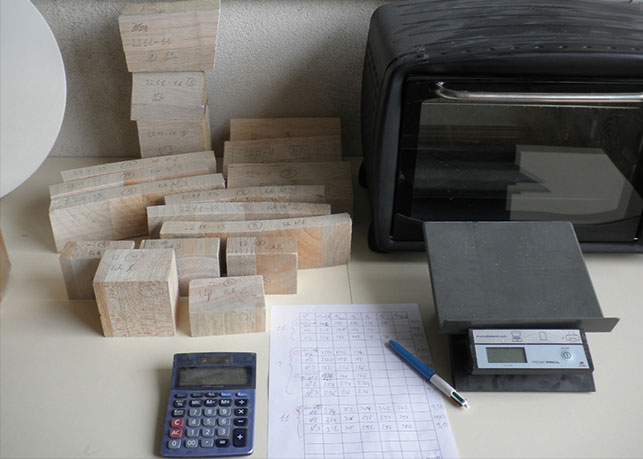

Trust us for the machining or machining subcontracting of your nuclear packaging wood. We are competent in the sourcing of wood and can carry out tests of the volumic mass to ensure that we respect your specifications exactly. We will then continue to shape your parts with our digitally controlled machines. Your parts will be checked for dimensions and humidity content. Then we carry out the large scale production of your parts, according to your needs.